High quality Z-A-M alloy coated steel

Product Features

|

Advantages |

Applications |

| • Vastly improved corrosion resistance

• Suitable for severe environments • Faster delivery than post-galvanized steel • Replaces need for higher coating weights • Raw edge protection • Concrete compatible • Scratch resistant • More economical than post-galvanized steel • No reduction in product performance • Attractive, satin matt finish |

• Farming and horticultural sheds

• Foundation structures supporting solar power panels • Guardrails • Crash barriers for bridges • Coastal streetlight facilities • Road sound absorbers, industrial sound absorbers • Cooling tower • Cable bridge and support system of urban underground pipe gallery • Car lift parking system outdoor • Distributing board • Roof, wall, steel curtain wall, sandwich panel |

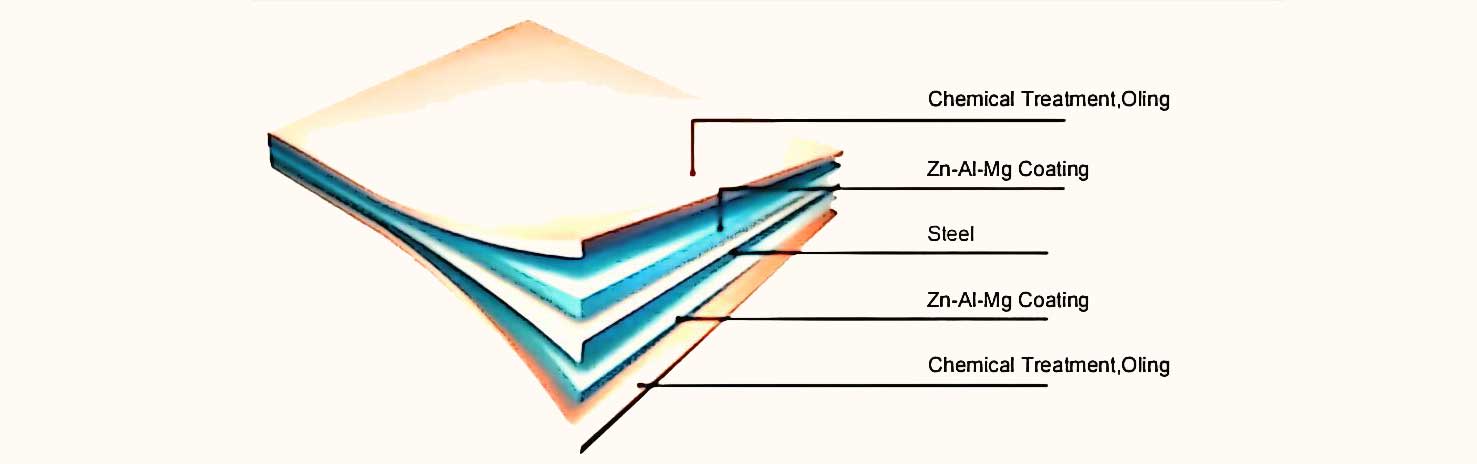

Product Structure

In addition to its corrosion resistance, Z-A-M Alloy Coating Steel also offers excellent strength and durability. The alloy coating is bonded to the steel at the molecular level, creating a material that is highly resistant to scratching, abrasion, and other forms of physical damage. This makes it an ideal material for use in applications where strength and durability are paramount, such as automotive components, building materials, and industrial equipment.

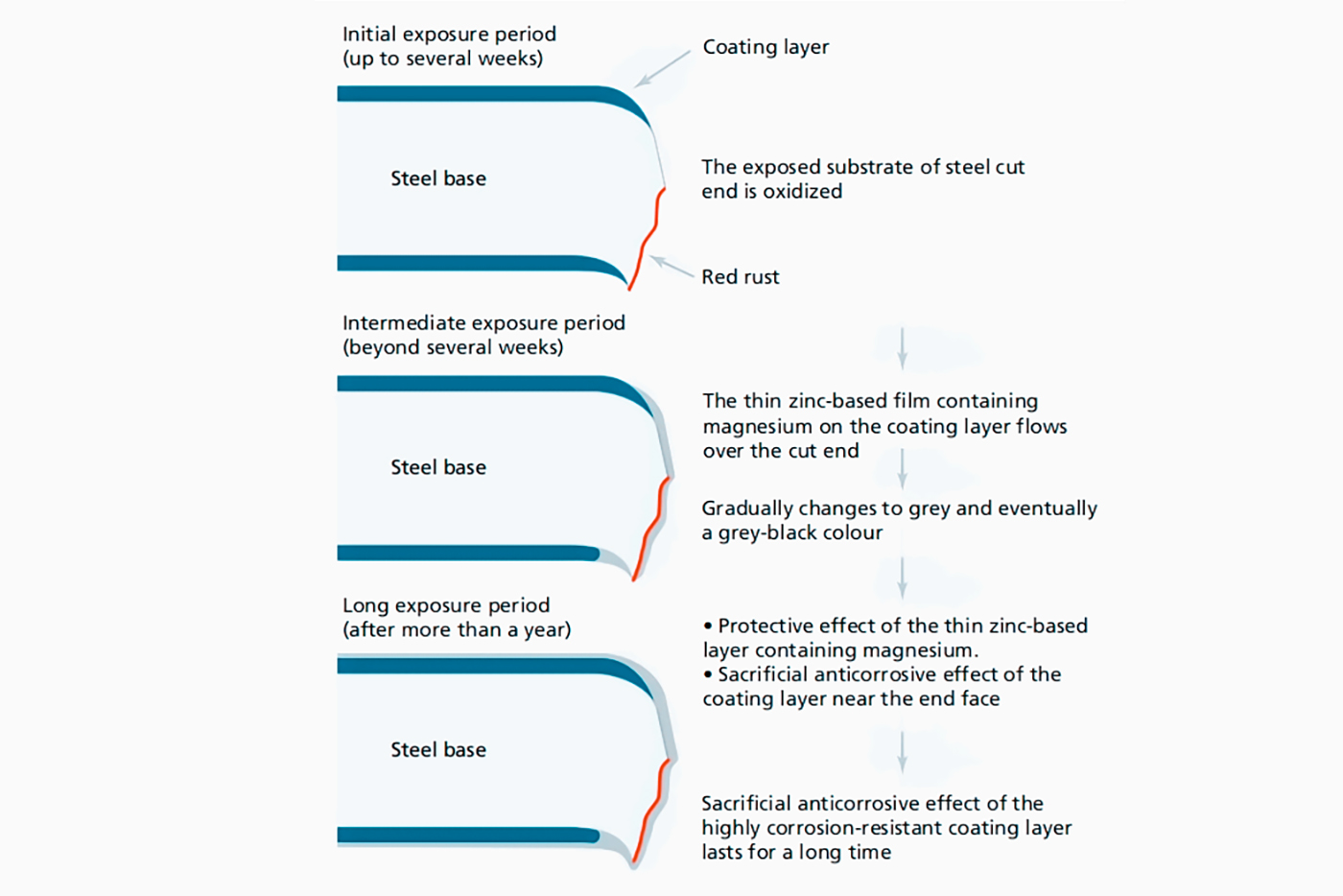

Product Raw Edge Protection

|

Z-A-M Alloy-Coated Steel |

||

| Brand | Posco (PosMAC® 1.5/3.0/Super) HBIS JISCO | |

| Standard | KS D 3030 ASTM 1046M DIN EN 10346 YB/T 4761 | |

| Grades | CQ DQ DDQ Structural (CR or HR) | |

| Coating Weight | 80 g/m2 to 630 g/m2 | |

| Thickness | 0.5 mm to 6.0 mm | |

| Width | 800 mm to 1650 mm | |

| Post Treatment |

Chemical Treatment |

Oiling |

| Chrome Treatment

Cr-Free Tlubrication Treatment No Treatment |

Oiled

Non-Oiled |

|

| MOQ | 25 Tons | |

| Coil Inner Diameter | 610 mm or 508 mm | |

| Delivery status | Coil, Strip, Sheet, Tube | |

WeChat

WeChat