Aluminized Steel (Standard Type 1)

Product Features

|

Characteristics |

Applications |

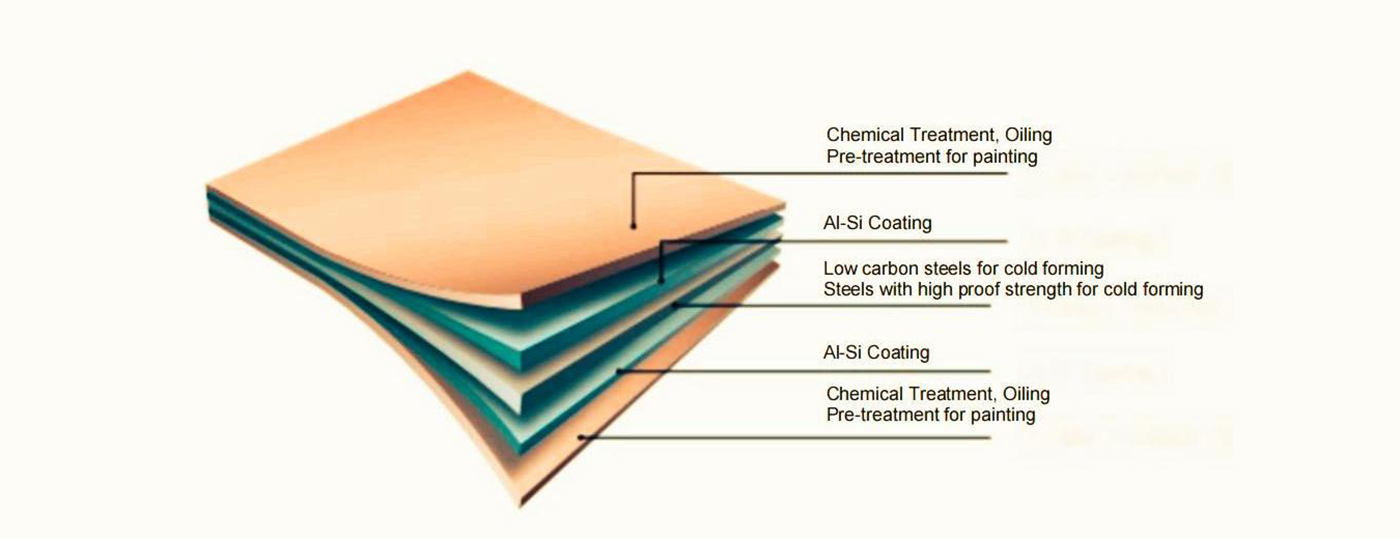

| • The effective control of the solidification and crystallization process of the molten aluminum layer enables it to form a beautiful surface

• Even surface and outstanding corrosion resistance due to the sacrificing effect of aluminum • Outstanding corrosion resistance / heat resistance, paintability |

• Home / Kitchen appliances

• Automobile parts • Painting and assembly systems • Steel cans |

Product Structure

Standard Comparison

| Classification | KS D3544 | JIS G3314 | ASTM A463 | DIN EN 10346 | GB/T 18592 |

| Commercial Quality | SA1C | SA1C | CQ | DX51D | DX51D |

| Drawing Quality | SA1D | SA1D | DQ | DX52D, 53D | DX52D, 53D |

| Extra / Deep Drawing Quality | SA1E | SA1E | DDQ-EDDQ | DX54D-DX56D | DX54D-DX56D |

Minimum Coating Weight (Double Side)

|

Coating weight symbol |

KS D 3544 |

JIS G 3314 |

ASTM A 463 |

DIN EN 10346 |

GB/T 18592 |

|

40 g/m² |

40 g/m² |

40 g/m² |

T1-13 (40 g/m²) |

||

|

60 g/m² |

60 g/m² |

60 g/m² |

AS 060 |

||

|

80 g/m² |

80 g/m² |

80 g/m² |

T1-25 (75 g/m²) |

AS 080 |

AS 80 |

|

100 g/m² |

100 g/m² |

100 g/m² |

AS 100 |

AS 100 |

|

|

120 g/m² |

一 |

120 g/m² |

T1-40 (120 g/m²) |

AS 120 |

AS 120 |

Aluminized Steel (Standard Type 1) is a versatile and durable material that has been coated with a thin layer of aluminum-silicon alloy through a hot-dip process. This coating enhances the steel's properties, making it highly resistant to corrosion and rust while maintaining the strength and hardness of traditional carbon steel. The aluminum-silicon alloy also gives the steel an attractive appearance, making it suitable for a wide range of applications.

One of the key features of Aluminized Steel (Standard Type 1) is its exceptional heat resistance. The aluminum-silicon alloy coating provides a protective barrier against high temperatures, making this material ideal for use in environments where heat is a concern. This makes it particularly well-suited for use in industrial equipment, automotive components, and other applications where exposure to high temperatures is common.

In addition to its heat resistance, Aluminized Steel (Standard Type 1) also offers excellent corrosion resistance. The aluminum-silicon alloy coating creates a barrier that protects the steel from moisture, chemicals, and other corrosive elements, ensuring that it remains in top condition even in harsh environments. This makes it a reliable choice for outdoor applications and other settings where corrosion resistance is essential.

Furthermore, Aluminized Steel (Standard Type 1) is known for its exceptional mechanical properties. It is a strong and durable material that can withstand heavy loads and high pressures, making it suitable for use in a variety of structural applications. Its combination of strength, durability, and corrosion resistance makes it a cost-effective and reliable choice for a wide range of industrial and commercial applications.

Overall, Aluminized Steel (Standard Type 1) is a high-quality material that offers exceptional performance in terms of heat resistance, corrosion resistance, and mechanical properties. Its versatility and durability make it a popular choice for a wide range of applications across various industries.

|

Aluminized Steel (Type 1) |

||

| Brand | Posco(ALCOSTA) ArcelorMittal(VAMA) HBIS Masteel | |

| Standard | JIS G3314 EN 10346 ASTM A463 GB/T 18592 | |

| Grades | Commercial Forming Deep Drawing High Strength | |

| Coating Weight | 80 g/m2 to 240 g/m2 | |

| Thickness | 0.3 mm to 3.0 mm | |

| Width | 600 mm to 1500 mm | |

| Post Treatment |

Chemical Treatment |

Oiling |

| Chrome Treatment

Cr-Free Tlubrication Treatment No Treatment |

Oiled Non-Oiled |

|

| Pre-Treatment For Painting | Vinyl Resin Paint Silicone Resin Painting

Phenolic Resin paint Polyurethane Resin Paint Lacquer Non-Paint |

|

| MOQ | 25 Tons | |

| Coil Inner Diameter | 610 mm or 508 mm | |

| Delivery Status | Coil, Strip, Sheet, Tube (For Automobile Exhaust System) | |

WeChat

WeChat